Confused about the labyrinth rear main seals that Ford used from 1932 to about 1941?

Consider the definition of Labyrinth: "An intricate structure of interconnecting passages through which it is difficult to find one's way; a maze."

So you see, the labyrinth seals are designed to be amazing, and confusing, to the engine oil. The oil is supposed to be confused, and then frustrated in its attempt to escape from the oil pan.

In a labyrinth seal, the fixed part(s) do not touch the rotating parts.

The seal is only effective when the engine is running and then only if the volume of oil directed at the seal, and the pressure differential, are not too great.

Before you say how terrible and archaic these seals are, consider that they are used in modern turbine engines, although not usually for oil control. (This info thanks to Phil Howard from Seattle).

The disadvantage is that they tend to leak oil, especially when the engine is stopped. If you stop on a hill in San Francisco , for instance, you better have the front of the car facing downhill before you shut off the engine!

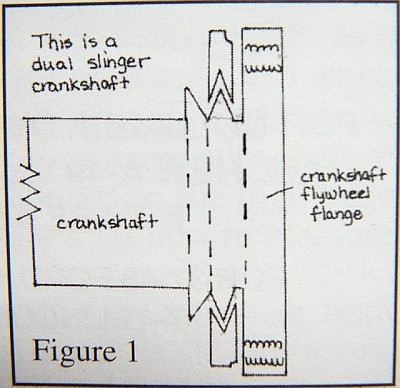

Labyrinth seals work by centrifugal force, slinging oil, and air, to the outside. From there the oil is supposed to drain through the hole in the pot metal piece, if there is a pot metal piece, and from the cap into the pan. Usually there is a drain tube in the cap which sometimes has a check ball in it.

The labyrinth seal might look like this in cross-section:  (Figure 1)

(Figure 1)

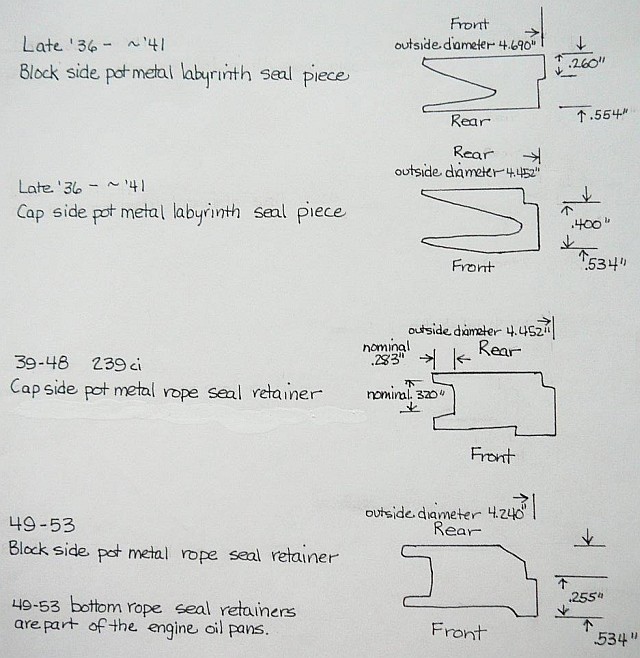

There were different combinations of parts used 1932-36 and 1936 - about 1941. Most of the 221 ci engines I see have labyrinth seals, while most of the 239 ci and all of the 255 ci engines have rope seals.

The labyrinth seals use no rope or rubber parts.

In the 1932 to mid-1936 engines, there is seldom a pot metal labyrinth seal piece in the rear main bearing cap. There is just a cavity that leads to the drain hole, and probably a tube. These earlier engines do have a pot metal labyrinth seal piece in the block.

From mid-1936 to about 1941, there also was also a lower pot metal seal piece that fit into a machined area in the cap. It should have a drain hole that matches the one in the cap.

Even after the rope seal was in use, the drain hole in the cap was generally used through 1948.

If you install a crankshaft without the rear of the two slingers, you should use a rope seal. If it is a 1936 to about 1941 engine, you may use the 239ci (1939-1948) parts to hold the rope seal, without doing machine work, if you use a later c/s.

For the 1932 - 36 style, you would have to make or buy a special lower pot metal piece. It is screwed to the rear main cap to hold the rope seal. Red's Headers has them.

To convert to a rope rear seal using a dual slinger crankshaft, the rear crankshaft slinger must be machined off. A smooth concentric seal surface must be created at its base. This can be done with a crankshaft grinder using a stone .615" wide or narrower. This stone should have generous corner radii.

So there you have it. In a nutshell, labyrinths have no rope or rubber pieces and no part of the seal touches the crankshaft. The crankshaft must have dual slingers.

Rope seals require different pot metal pieces and the crankshaft has no rear, of two, slingers, but rather a smooth seal surface.

The crankshaft, the pot metal piece(s), and the rope seals, if any, must all match.

Now you are out of the maze.