What is Plastigage -- should it be used – and if so, how do you use it?

Plastigage is an accurately made round plastic thread with known deformation properties. It comes in three diameters and colors. It is color coded by size -- green Plastigage measures the range .001 - .003”, red measures .002 - .006: and Blue .004 - .009”. In each case the measurements in the top 1/3 of the range are suspect and should be be verified by using the next size larger if possible.

Illustration #1

Why would you want to use Plastigage? It is a check on the machining accuracy and the possible stack up of tolerances that determine plain bearing running clearance. The three things that effect the clearance are the shaft outside diameter the bearing thickness the housing inside diameter.

Other items, like dirt or any foreign material, can affect the clearance but they should not be allowed.

Because the typical journal diameter specification on a crankshaft is a range of about .001”; bearing thicknesses vary perhaps .0005” from brand to brand ; and the housing diameter specification is typically about .001” wide, you can see that even with all dimensions within specification you may end up with clearances something other than what you need or want. In our engines the housing is the block and main caps or the rods and rod caps. If one or more of the items are out-of-spec then the problem can become much worse. Using Plastigage can help you find problems during assembly that can be more inexpensively corrected then. Much better than after parts are ruined by running with the wrong clearances.

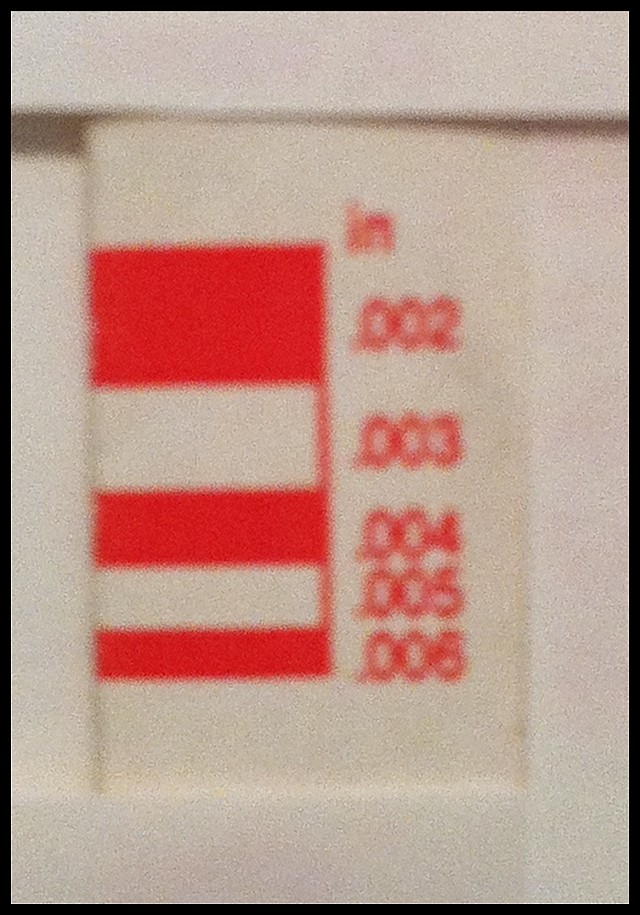

Use of Plastigage is simple. The shaft journal must be clean, and so should the bearing shells and the housing bore. Install the bearings dry, without lubricants. Oil takes up space, and grease uses more space. Lubricate the threads of the nuts and studs, or bolts, and the thrust area under the heads of the bolts or nuts. Assemble the bearing cap with the Plastigage across the bearing shell lengthwise with the shaft at 90 degrees to the parting line. Torque to the correct value – do not turn the shaft. Remove the cap and bearing shell. The Plastigage, if of the correct range, will be flattened. This should be compared with the widths printed on the Plastigage wrapper to determine the clearance. Since you are measuring the width of the deformed plastic, and the calibration key is on the packaging, this is a system where you never throw away the product wrapper.

Illustration #2

If the Plastigage width shows that the clearance is what you want, and in the lower 2/3 of the range, clean all of its plastic residue from the shaft journal and the bearing shell and you are ready for oil or assembly lube and final assembly. If it is not within tolerances, the problem needs to be corrected. Then you re-check with Plastigage to ensure that the correction worked as intended.

I have found mis-packed and mislabeled bearing shells as well as crankshafts machined to the wrong specifications in this way. Sometimes I have failed to identify a problem that has come back to hurt me later due to not using Plastigage. The adage “trust, but verify” comes to mind.

When spelled Plastigauge, the product is then a trademarked product of Plastigauge Ltd, W Sussex, UK.