Lubrication

You will need to select the oil pump that will be used in your engine. There are two small gear and two large gear pumps that I know of. Sometimes the small gear pumps are called 50 lb pumps and the large gear 80 lb pumps. This is the pressure that they would be expected to make in a fresh tight engine.

The earlier large gear pump has straight cut gears and a long body like the small gear pumps. The 49-53 pump has a short body and helical gears. There is also a new high volume pump that has been reissued by Melling that is short body. It uses larger helical gears than any of the stock pumps.

I usually use the new 49-53 short body pumps. They cost less than the earlier rebuilt pumps. They require a 48-53 truck oil pump pickup to use in 32-48 engines and may also need a baffle removed or modified in the early pan.

If you were setting up a race engine for endurance events, you might want to use the high volume pump. I don't think that it is needed in most engines. You may want to consider one of the two full flow oil filtering options available if the engine is not destined for a restored, judged vehicle.

Cooling

The most important thing is to start with a block without cracks. If you don't let any combustion gases get into the coolant, you should be able to cool any bore size flathead. Heads and head gaskets are part of the combustion chamber too. Combustion gases leaking into the coolant will make any engine almost impossible to cool.

The remainder of the cooling system matters too. It has to contain the coolant, circulate and cool it. Most flatheads seem to run cooler with thermostats or other restrictors between the heads and the radiator. Be sure to use something in the coolant that inhibits corrosion in the system. Standard antifreeze/coolant product solutions usually contain anti-corrosives.

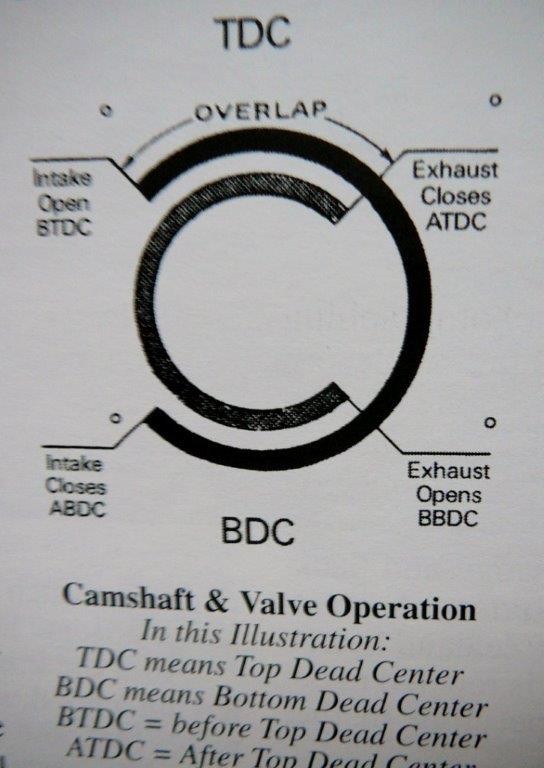

Cam Grind Selection

In a stock restored engine you should install a stock cam. I have seen stock flatheads idle smoothly at 180 rpm.

If you don't have the need for a stock idle, cams may be selected that increase higher RPM performance at the expense of low end. This creates the familiar "lope" sound heard in idling hot rods.

Cam duration is measured in crankshaft rotational degrees and determines the best RPM range of an engine. Valve lift is measured in thousandths of an inch – more lift usually adds power throughout the RPM range.

The larger the displacement in the engine, the more cam timing you can use and still maintain an acceptable idle. What is an acceptable idle? Whatever makes you happy with the engine's performance in its intended use.

In small displacement engines, cams of around 248 degrees usually give good idle. In 255 to 275 cubic inch engines, 254 degrees is a common choice. Track cams combine high lift with relatively short duration. Cam grinds for all out straightaway events will be long duration – perhaps approaching 300 degrees.