How can you tell if a head has been excessively machined? This rule may be handy when you are checking out heads at a swap meet, or don't have your depth mic handy.

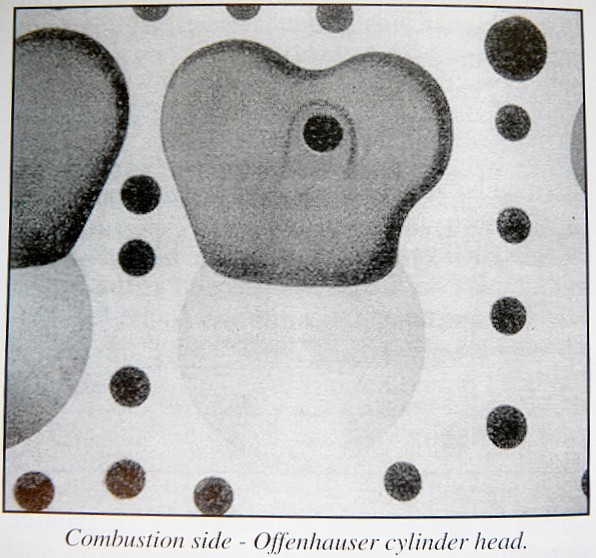

Note that the dome that forms part of the chamber in the heads is typically about 3.3" in diameter for 3-3/16" bore engines. This puts the edge of it about 0.3" from the bolt holes, around the domes. Look at the heads that you have to get an idea of the sizes and relationships.

The angle of the dome is shallow, relative to the surface of the head. This means that as the head has material removed during resurfacing, the dome decreases in size rapidly. The edges of the domes also become further from the bolt holes around them.

You may also compare the sizes of the domes in the end chambers to those in the inner chambers. Heads typically warp with the center up, away from the block. Aluminum heads may be warped so much that the end domes, and chambers, become much smaller than the inner chambers.

Some shops have the ability to straighten an aluminum cylinder head before surfacing. This allows all of the chambers to stay about the same volume. Some heads would sooner break than be straightened. (Do you know any one like that?) If your shop breaks your aluminum head during straightening process, it is probably not their fault.

Warping causes compression imbalance and may cause the piston(s) to hit the head.

Illustration #1

Here is an easy way to check valve and piston to head clearance. When all is ready for the heads to be put on, put them on with no head gaskets. Put them on the side where they will run. On studded engines, just slide them on the studs and hold them down with your hands. Get a helper (Thank you, Marilyn) to turn the engine over. The spark plugs should not be installed. If the valves or pistons don't hit the head, the gasket will add enough height for adequate clearance.

On engines with bolts, use two studs or two threaded pins or two head bolts not tightened to locate the head. Otherwise it is the same procedure.

What if you feel the head lift up under your hands? You can usually tell what is hitting by where the head lifts up. You can use china markers or light grease to see for sure.

If you rock the engine back and forth to pick up the head as far as it goes, you can use a feeler gauge between the head and the block to measure the amount of interference.

Remember that, without the head gasket, you need only relieve the interference to zero -- the thickness of the gasket will be enough clearance.

What if you don't want to remove metal in the combustion chamber(s) to get rid of interference? Peter Harding of Gardnerville NV tells me of a business that makes copper shim gaskets -- or these can be used as gasket spacers. The name is SCE Gaskets, 1-800-427-5380 or www.SCEGaskets.com